Food/Seasoning

Multi-layer bottles for food and seasoning with barrier layer to prevent oxidization and extend shelf life has become the mainstream. There are many bottles that are displayed at supermarkets that are produced by our blow molding machine.

Extrusion blow molding machine enables to produce bottles with handles without secondary process after taking out from molding machine. We offer the most suitable blow molding machine meeting your demands with our extensive experiences.

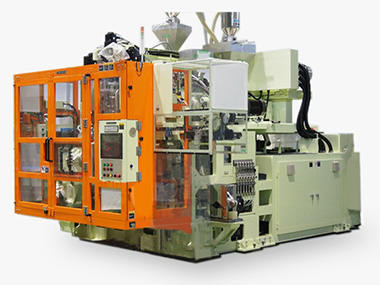

For multi-layer seasoning bottle

Machine Model: MSD-C46A/64MKZ2-AP(C4)

No. of station: Double station

Bottle capacity : 100mL~1L

Die head: 4 parisons

Center distance: 150mm

Screw diameter: φ65/φ40/φ30×2

Clamping force: 150kN

Layer composition: 6-layer 4-kind of resin

| Inner Layer | Outer Layer | ||||

|---|---|---|---|---|---|

| LDPE | REG | AD | EVOH | AD | LDPE |

For multi-layer seasoning tube

Machine Model: MSD-C56V/43M-AP(C2)

No. of station: Double station

Bottle capacity : 10mL~300mL

Die head: 2 parisons

Center distance: 150mm

Screw diameter: φ50/φ35×2/φ25×2

Clamping force: 50kN

Layer composition: 6-layer 4-kind of resin

| Inner Layer | Outer Layer | ||||

|---|---|---|---|---|---|

| LDPE | REG | AD | EVOH | AD | LDPE |

Consumer/Daily packaging

Variety of small-lot products can be produced with one widely useable Extrusion blow molding machine.

Value-added products can be made by adding view-stripe, using glossy resin for outer layer or making highly-designed shape.

For wide capacity range of daily packaging

Machine Model: MSE-55E/54M-AP(E2)

No. of station: Single station

Bottle capacity : 100mL~1L

Die head: 2 parisons

Center distance: 170mm

Screw diameter : φ55

Clamping force: 70kN

Resin: PE/PP

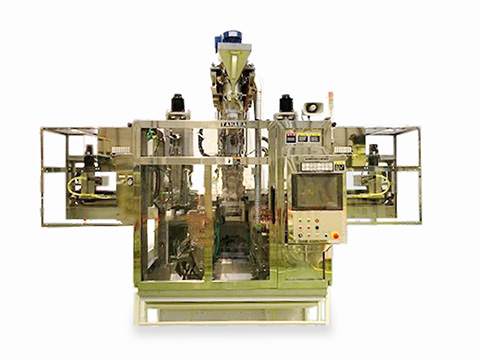

For multi-layer shampoo bottle which have glossy outer layer

Machine Model: MSD-C44A/43R-AP(C2)

No. of station: Double station

Bottle capacity: 50mL~500mL

Die head: 2 parisons

Center distance: 120mm

Screw diameter: φ45/φ30/φ25×2

Clamping force: 50kN

Layer composition: 4-layer 4-kind of resin

| Inner Layer | Outer Layer | ||

|---|---|---|---|

| LDPE | REG | AD | EVOH |

For mass lot production of daily packaging

Machine Model:INNOVAREX400D

No. of station:Double station

Bottle capacity:0.5L~10L

Die head:3 parisons~12 parisons

Center distance:85mm~350mm

Screw diameter:φ90/φ65/φ65/φ35

Clamping force:400kN

Layer composition:3-layer +view stripe

Layer ratio:20%/60%/20%+view

Printing

Toner cartridges for printers can be also produced with Extrusion blow molding machine.

Our blow molding machine produces highly compatible product with copier or accessories stably because of high repeatability.

We have wide experience of Extrusion blow molding machine for from business-use big toner cartridge to home-use small cartridge.

For thin and wide shape of toner cartridge of copier for business-use

Machine Model: MB-70E/54L-AP(E1)

No. of station: Single station

Bottle capacity: 500mL~5L

Die head: 1 parison

Center distance: –

Screw diameter: φ70

Clamping force: 120kN

Resin: PE/PP

For small cartridge of home-use printer

Machine Model: MSD-70E/53M-AP(E4)

No. of station: Double station

Bottle capacity: 30mL~300mL

Die head: 4 parisons

Center distance: 90mm

Screw diameter: φ70

Clamping force: 70kN

Resin: PE/PP

Industrial packaging

We design any layer composition that you demand for an inner package of bag in box and chemical bottle. Our blow molding machine enables to produce quality product with stable product shape and layer composition because of high repeatability, which makes safety transport possible.

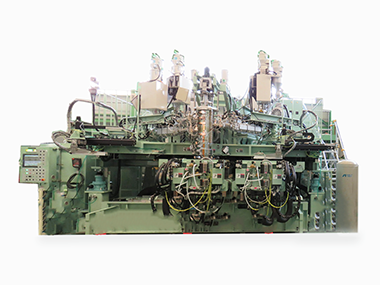

For multi-layer industrial chemical bottle

Machine Model: MFL-C33A/76LJ-A(C1)

No. of station: Single station

Bottle capacity: 10L~20L

Die head: 1 parison

Center distance: –

Screw diameter: φ100/φ65×2

Clamping force: 300kN

Layer composition: 3-layer 3-kind of resin

| Inner Layer | Outer Layer | |

|---|---|---|

| HMWPE | REG | HMWPE |

For inner bag of bag-in-box

Machine Model: MF2L-90E/65L2J-A(E1)

No. of station: Single station

Bottle capacity : 10L~20L

Die head: 1 parison

Center distance: –

Screw diameter: φ90

Clamping force: 350kN

Resin: LDPE

| Inner Layer | Outer Layer | |

|---|---|---|

| HDPE | REG | HDPE+MB |

| HDPE(VS) | HDPE(VS) |

For single-layer or multi-layer Jerry Can

Machine Model: TJS25A-M

No. of station: Single station

Bottle capacity : 5L~20L

Die head: 1 parison

Center distance: –

Screw diameter: φ80/φ50/φ50

Clamping force: 250kN

Layer composition: 3-layer 3-kind of resin

Layer ratio:20%/60%/20%

| Inner Layer | Outer Layer | |

|---|---|---|

| HDPE | HDPE | HDPE |

| HMWPE | HMWPE | HMWPE |

Pharmaceutical/Sanitation

Pharmaceutical bottle requires clean environment and exact shape. Demand of antiseptic bottles has been increasing due to recent corona virus that are also our advantage of fully electric blow molding machine. Fully electric control realizes eliminating risk of oil adhesion and high repeatability of the machine movements stabilizes product quality.

For spray bottle of antiseptic liquid

Machine Model: MSD-90E/64M02KZ2-AP(E4)

No. of station: Double station

Bottle capacity : 100mL~1L

Die head: 4 parisons

Center distance: 120mm

Screw diameter: φ90

Clamping force: 150kN

Resin: PP/PE

Customized for clean room-use for infusion bottle

Machine Model: MSD-55E/54NZ-A(E4)

No. of station: Double station

Bottle capacity : 30mL~300mL

Die head: 4 parisons

Center distance: 90mm

Screw diameter: φ55

Clamping force: 70kN

Resin: PE/PP

Automobile/Motorcycle

Related with CASE innovation, automobile parts become lighter and lighter by replacing metal parts with plastic. We have had the experience of the blow molding machines for automotive parts such as fuel tank and boot shaft. We are willing to challenge to develop new product with our clients.

For multi-layer fuel tank

Machine Model: MSD-C66A/74L-A(C1)

No. of station: Double station

Bottle capacity : 1L~10L

Die head: 1 parison

Center distance: –

Screw diameter: φ80/φ70/φ55/φ35×3

Clamping force: 200kN

Layer composition: 6-layer 6-kind of resin

| Inner Layer | Outer Layer | ||||

|---|---|---|---|---|---|

| HMWPE | AD | EVOH | AD | REG | HMWPE+MB |

For boot shaft of automobile

Machine Model: HPS-50E/05B(T2)

No. of station: Single station

Bottle capacity : 50mL~500mL

Die head: 2 parisons

Center distance: 170mm

Screw diameter: φ50

Clamping force: 50kN

Resin: Elastomer

Large product

Since the October 2021, blow molding machine business for large product has been transferred to TAHARA from JSW, which also includes all of sales, manufacturing, and service maintenance for the future business. A plastic drum, an automotive spoiler, and a large general-purpose tank that were previously out of our targets became possible to produce by TAHARA.

We are also able to produce both continuous extrusion head and accumulator head depending on the requirement.

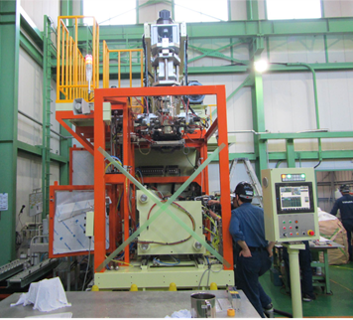

Large blow molding machine for 200L plastic drum with 3 layers

Machine Model: NEB80/P90*3/W300ML

Station: Single station

Bottle capacity: 200L

Die head: 1 parison

Center distance: –

Screw diameter:φ90mm x 3

Clamping force:800kN

Layer composition: 3-layer 3-kind of resin

| Inner Layer | Outer Layer | |

|---|---|---|

| HDPE (clean & natural) | HDPE (Including REG) | HDPE (Including MB) |

Large blow molding machine for automotive spoiler

Machine Model: NB60SII

Station: Single station

Die head: 1 parison

Center distance: –

Accumulating capacity:9L

Screw diameter:φ120

Clamping force:600kN

Resin: ABS material

Products

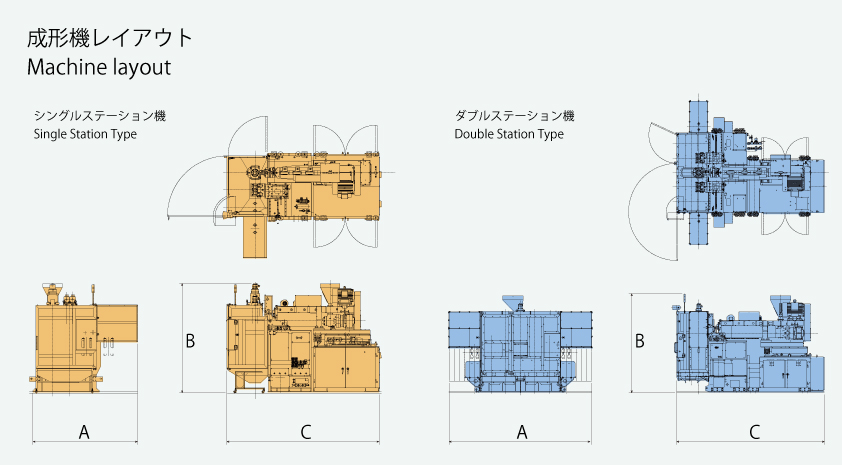

Single Station Machine

The list of our machines is below. In addition, we manufacture machines on your specification.

| MSE-35D/32M | MSE-45E/43M | MSE-55E/54M | MSE-70E/65LKZ2 | MB-65E/54M | MB-80E/65C | MF-100F/76LJ | |

|---|---|---|---|---|---|---|---|

| Extruder Diameter*1 | φ35 | φ45 | φ55 | φ70 | φ65 | φ80 | φ100 |

| Clamping Force (kN) | 30kN | 50kN | 70kN | 150kN | 120kN | 200kN | 200kN~300kN |

| Max. Mountable Mold Width (mm)*2 | 220mm | 280mm | 380mm | 600mm | 380mm | 550mm | 740mm |

| Max. Mountable Mold Height (mm) | 240mm | 300mm | 370mm | 480mm | 415mm | 520mm | 620mm |

| Max. Mountable Mold Thickness (mm) | 85mm (One side) |

95mm (One side) |

120mm (One side) |

150mm (One side) |

120mm (One side) |

95mm (One side) |

280mm (One side) |

| Daylight (The space between platens) (mm) | 280mm | 320mm | 420mm | 600mm | 420mm | 500mm | 1000mm |

| Mold Slide Stroke (mm) | 240mm | 300mm | 395mm | 650mm | 395mm | 650mm | 850mm |

| Machine Layout Width (mm) *A | 1170mm | 2100mm | 2420mm | 3510mm | 2250mm | 3315mm | 2700mm |

| Machine Layout Height (mm) *B | 2350mm | 2460mm | 2520mm | 3095mm | 2625mm | 3085mm | 3810mm |

| Machine Layout Depth (mm) *C | 2690mm | 3200mm | 3515mm | 4620mm | 3715mm | 4390mm | 5770mm |

| Machine Weight (ton) | approx3.0ton | approx4.5ton | approx6.0ton | 15.0ton | approx10.0ton | approx10.0ton | approx20.0ton |

| Dry Cycle Time (sec) | 2.0s | 2.2s | 2.2s | 4.0s | 2.8s | 4.5s | 6.0s |

| Two Parisons Pitch (mm)*3 | 90mm | 120mm | 170mm | 220mm | 170mm | 230mm | |

| 4 Parisons Pitch(mm) | 45mm | 60mm | 80mm |

*1 : We offer 13 types of extruders in φ20 – φ100 diameter.

*2 : Beside the list, we offer clamping units in various size and clamping force on your needs.

*3 : We propose the number of heads on your needs.

Double Station Machine

The list of our machines is below. In addition, we manufacture machines on your specification.

| MSD-40E/32M2 | MSD-55E/43M | MSD-70E/54M | MSD-90E/65MK | MBD-80E/54M | MBD-90E/65F | MFD-100F/76LJ | |

|---|---|---|---|---|---|---|---|

| Extruder Diameter*1 | φ40 | φ55 | φ70 | φ90 | φ80 | φ90 | φ100 |

| Clamping Force (kN) | 30kN | 50kN | 70kN | 150kN | 120kN | 200kN | 200kN~300kN |

| Max. Mountable Mold Width (mm)*2 | 220mm | 280mm | 380mm | 530mm | 415mm | 530mm | 740mm |

| Max. Mountable Mold Height (mm) | 240mm | 300mm | 370mm | 480mm | 415mm | 470mm | 620mm |

| Max. Mountable Mold Thickness (mm) | 90mm (One side) |

95mm (One side) |

120mm (One side) |

120mm (One side) |

120mm (One side) |

175mm (One side) |

280mm (One side) |

| Daylight (The space between platens) (mm) | 280mm | 320mm | 420mm | 460mm | 420mm | 770mm | 1000mm |

| Mold Slide Stroke (mm) | 240mm | 330mm | 425mm | 565mm | 425mm | 950mm | 1350mm |

| Machine Layout Width (mm) *A | 2530mm | 3724mm | 4214mm | 5548mm | 4349mm | 5120mm | 4730mm |

| Machine Layout Height (mm) *B | 2525mm | 2507mm | 2610mm | 3243mm | 2915mm | 3500mm | 3810mm |

| Machine Layout Depth (mm) *C | 4208mm | 3465mm | 4350mm | 5070mm | 4600mm | 5100mm | 6560mm |

| Machine Weight (ton) | 7.0ton | 9.0ton | 10.0ton | 19ton | 11.0ton | 22.0ton | approx32.0ton |

| Dry Cycle Time (sec) | 2.1s | 2.5s | 3.5s | 4.0s | 3.5s | 5.7s | 6.0s |

| Two Parisons Pitch (mm)*3 | 90mm | 120mm | 170mm | 240mm | 170mm | ||

| 4 Parisons Pitch(mm) | 45mm | 60mm | 80mm | 120mm | 90mm |

*1 : We offer 13 types of extruders in φ20 – φ100 diameter.

*2 : Beside the list, we offer clamping units in various size and clamping force on your needs.

*3 : We propose the number of heads on your needs.

Multilayer Molding Machine

The list of our machines is below. In addition, we manufacture machines on your specification.

| MBD-C46V/54M-AP(C2) | MSD-C44A/64MKZ2-AP(C4) | MBD-C55A/54M-AP(C2) | |

|---|---|---|---|

| The Number of Layers | 6 layers | 4 layers | 5 layers |

| Layer Composition (Inner Layer – Outer Layer) | PE/REG/AD/EVOH/AD/PE | HDPE/REG/HDPE+ (HDPE(View Stripe)) |

PA/AD/REG/HDPE+ (HDPE(View Stripe)) |

| Use | Seasoning / Food / Cosmetics | Automotive Oil / Daily Necessities | Agricultural Chemicals |

| Extruder Diameter*1 | φ40・35・20・20 | φ80・70・65・30 | φ65・40・40・35・30 |

| The Number of Parisons*2 | 2 | 4 | 2 |

| Head Pitch | 240mm | 140mm | 180mm |

| Clamping Force (kN) | 70kN | 150kN | 70kN |

| Max. Mountable Mold Width (mm)*3 | 380mm | 600mm | 380mm |

| Max. Mountable Mold Height (mm) | 415mm | 410mm | 415mm |

| Max. Mountable Mold Thickness (mm) | 120mm(One side) | 120mm(One side) | 120mm(One side) |

| Daylight (The space between platens) (mm) | 420mm | 460mm | 420mm |

| Mold Slide Stroke (mm) | 425mm | 650mm | 425mm |

| Max. Capacity of the Container (L)*4 | 150mL | 1000mL | 1000mL |

| Min. Capacity of the Container (L)*4 | 30mL | 100mL | 100mL |

| Machine Layout Width (mm) *A | 3230mm | 6024mm | 3230mm |

| Machine Layout Height (mm) *B | 3230mm | 3720mm | 3230mm |

| Machine Layout Depth (mm) *C | 5000mm | 5905mm | 5100mm |

| Machine Weight (ton) | 15ton | 25ton | 15ton |

| Dry Cycle Time (sec) | 4.0s | 5.0s | 4.0s |

*1 : We offer 13 types of extruders in φ20 – φ100 diameter.

*2 : We propose the number of heads on your needs.

*3 : Beside the list, we offer clamping units in various size and clamping force on your needs.

*4 : Capacity of the containers may vary depending on their shape.

Machine Layout Width (mm) *A

Machine Layout Height (mm) *B

Machine Layout Depth (mm) *C

Parts Store

Parts Store