Plastic bottles are necessity for our daily life. For example, shampoo or body soap that we use when washing hair or body, sunscreen cream that we use heavily especially in summer, mayonnaise that we use when making potato salad, and so on. All of these are in plastic bottles. And these plastic bottles are made by one of the molding methods called “Extrusion Blow Molding”.

So, what is “Extrusion Blow Molding”? Plastics as base material of plastic bottles soften when it is heated up and harden when it is cooled down. The extrusion blow molding method is one of the molding methods that utilize this property of plastics.

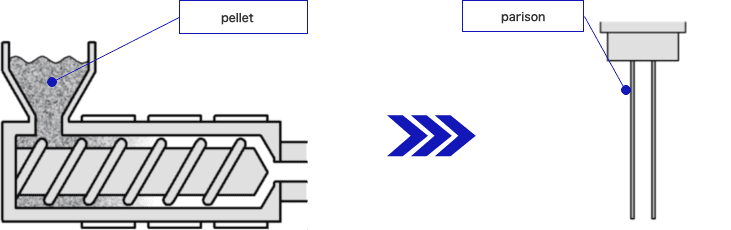

Softening the base material, plastic pellet, by heating in approximately 200℃, extrude it from the machine with tube form. This tube form melted plastic is called parison.

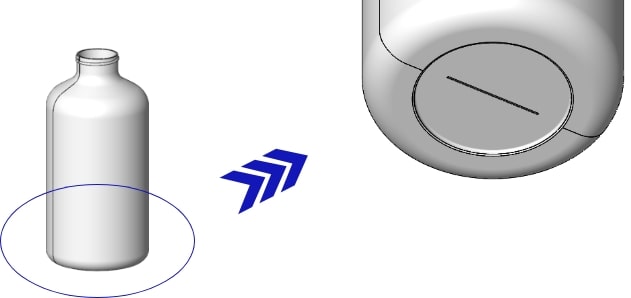

Clamp the extruded parison with molds that have hollowed shapes of the planned product, and blow air directly into the molds. By inflating, parison is pressed against the inside of molds and formed same shape as molds have. Parison that is pressed against the inside of molds is cooled down and hardened, when it comes off from the molds, the plastic bottle is formed. It is also called the Chūkū (中空) molding method in Japanese because of forming hollow bottle.

Advantage of the Extrusion Blow Molding

Three Major Advantages

・It suits for the small lot production of various shapes.

Because it does not require replacing many parts when changing the type of molding products, the set-up time is shortened. Besides, the molds for the extrusion blow molding machines are manufactured on a low-budget compared

to the stretch blow molding and injection blow molding machines so that the initial investment on the new production line is reduced.

・It is capable of molding irregular shape products; container with handle.

The irregular shape products such as container with handle are also molded same as regular shape products. It does not require the post-process of putting in handle to the molded products. Because the irregular shape

products are molded in only one process, extra units for post-process are unnecessary.

・It is capable of the multilayered molding.

When molding products, our machines create multilayers by using various types of plastic resin. It allows products having additional values as follows.

- Giving products antioxidant function by using plastic resin with oxygen barrier properties.

- Giving products glossy surface.

- Giving products to have reproduction layer by using recyclable material.

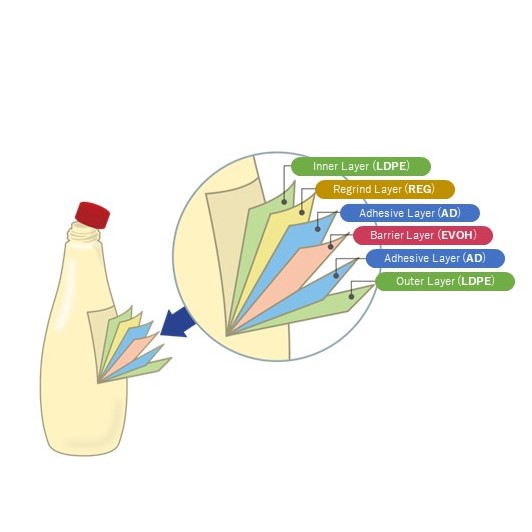

Multilayered Molding

The one major advantage of the extrusion blow molding method is ability to mold multilayer. The multilayer molding is to create and mold multilayer at once by using various plastic resins; thus, this molding method gives

additional values to the products.

The plastic has various functions depending on the kinds. The plastic resins commonly used for the extrusion blow molding are HDPE (high density polyethylene), LDPE(low density polyethylene), PP (polypropylene) that are

inexpensive and easy-to-use type; yet, their weakness sides are easily oxidized and less glossy finish. Making up for their weaknesses, the high function plastic resin such as EVOH (ethylene-vinyl alcohol copolymer) and

PA (polyamide) that high antioxidant and glossy finish type are used for the multilayer molding. Unfortunately, those high functional type plastics are also high in their price; therefore, molding product only using

those types of plastic rises a unit cost per product. Comparing to the commonly used plastics, a molding difficulty only using high functional plastics is higher and unsuitable for molding at all. So, the multilayer

molding is developed; as for this molding style, high functioning plastics are used for minimum amount and the commonly used plastics are used for the rest.

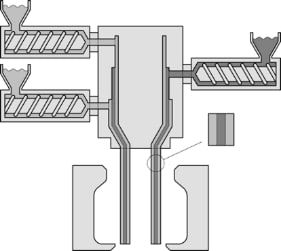

The multilayer molding machines extrude layered parison. The extrusion molding machines are usually equipped with one extruder; the machines capable of the multilayer molding have more than one extruder depending on the required number of plastics resins. Various plastics resins are flowing into the Head unit via each extruder to become one multilayered parison. Once multilayered parison is extruded, it goes same molding manner as single-layer molding machines.

Advantage of the Multilayer Molding

Multilayer molding has 2 major advantages. The one is to add extra values by using various kinds plastic resins, and the other is to reduce the material costs by using regrind plastic resin.

①Adding Extra Values

・Antioxidant Bottles

Most commonly used plastic bottles in our daily life are food related bottles such as for mayonnaise or seasonings. Because plastic bottles that are molded by only using HDPE or LDPE plastic resins are not able to block oxygen penetration, the contents quickly go bad. Laying the layer of EVOH plastic resin in between layer of HDPE or LDPE, it lets bottles to block oxygen penetration.

・Anti-volatilization Bottles

EVOH plastic resin is capable to prevent the contents from volatilizing. When storing gasoline in plastic bottles that are molded by only using HDPE plastic resin, gasoline is to volatilize. So, EVOH plastic resin is

used, same manner as bottles for food, to prevent gasoline from volatilizing.

・Chemical Resistant Bottle

Plastic bottles for storing chemicals are molded by using PA plastic resin. HDPE plastic resin has low performance in chemical resistance. If the layer of HDPE contacts any chemicals, the contents of bottles may

penetrate or the bottles may deform. In order to prevent this from happening, PA plastic resin layer is laid innermost layer of bottles. PA plastic resin has excellent performance in chemical resistance. Using PA plastic

resins gives bottles to have high performance in the permeation prevention and the deformation prevention.

・High Design Bottles

When aiming to mold plastic bottles having high design, EVOH or PET-G plastic resins are used outermost layer. HDPE plastic resin cannot give bottles to have glossy finish; it is disfavor for bottles that are expected

having luxurious finish such as for cosmetics related. Using EVOH or PET-G plastic resins outermost layer of bottles adds bottles luxurious feel.

②Reducing the Material Costs

・Utilize Regrind Plastic Resins

In a process of extrusion blow molding, some wastes called flash are produced Flash is commonly recycled as regrind plastic resin; yet, some contents are not allowed to contact layer of regrind plastic resin due to the

properties. In such case, putting the regrind layer in between other kinds of plastic resin to avoid the content contacting the regrind layer

For single layer molding machine, flash is waste. Multilayer molding lets flash to be recyclable plastic so that the material cost and loads on the environment are reduced.

・Saving Pigment Plastic Resin

Pigment plastic resin is used to mold colored plastic bottles. Because using pigment plastics, colored bottles are relatively costly comparing to the colorless bottles. Multilayer molding is very effective to reduce in

this cost increase. In multilayer molding process, plastic resin layer with pigment is laid outside and plastic resin layer without pigment is laid inside.

| Example of Usage | Number of Layers | Inner Layer | Outer Layer | Purpose of Usage | ||||

|---|---|---|---|---|---|---|---|---|

| Mayonnaise bottle | 6 | LDPE | REG | AD | EVOH | AD | LDPE |

Protection against oxidation Usage of recycled material |

| Salad dressing bottle | 6 | PP | REG | AD | EVOH | AD | PP |

Protection against oxidation Usage of recycled material |

| Fuel oil bottle | 6 | HMWPE | AD | EVOH | AD | REG | HMWPE |

Protection against volatilization Reduction in usage of pigments Usage of recycled material |

| Cosmetics bottle | 5 | PP | AD | EVOH | AD | PP | Protection against Permeation | |

| Agricultural chemical bottle | 5 | PA | AD | REG | HDPE |

Chemical resistance Usage of recycled material Making the remainings visible |

||

| HDPE(VS) | ||||||||

| Home / Personal care bottles | 4 | HDPE | REG | AD | PET-G |

Gloss finish Usage of recycled material |

||

| Sunscreen bottle | 4 | HDPE | REG | AD | EVOH |

Gloss finish Usage of recycled material Easy label printing |

||

| Motor oil bottle | 3 | HDPE | REG | HDPE |

Reduction in usage of pigments Usage of recycled material |

|||

REG:Regrind Plastic Resin

AD:Adhesive Plastic Resin

VS:View Stripe (For checking remainings)

Parts Store

Parts Store