What bottle can we make with our Blow molding machine? Multi-layer package Part 1

2/1/22

Multi-layer package Part 1

What would you do if you add more value to your plastic products for differentiation?

We’ll offer some suggestions divided into several times!

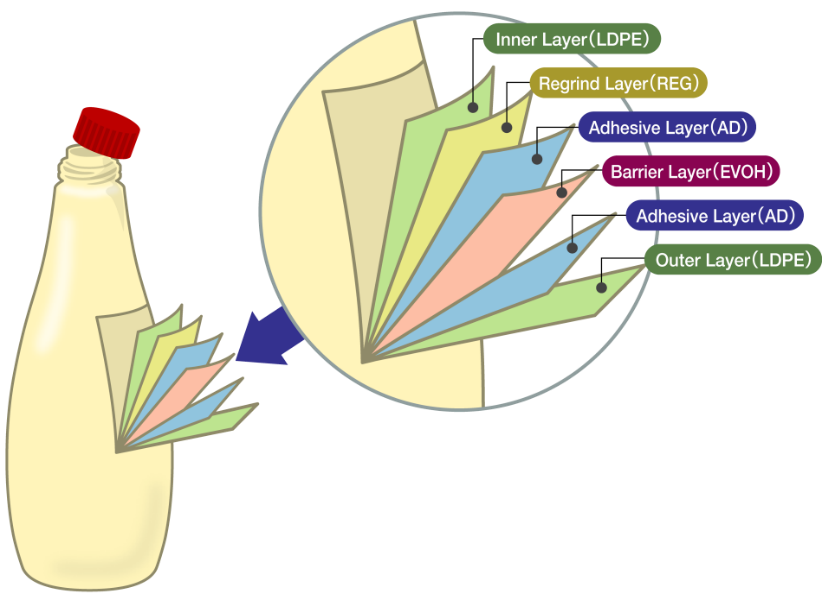

In this issue, we’ll introduce multi-layer package. Multi-layer package consists of more than 2 layers to add useful functions. Its laminated wall consists of PE/PP and other functional resin layers. Common purposes are like preventing from oxidization or volatilization, adding chemical resistance, making appearance of the package attractive or reducing the amount of resin to use. These valuable bottles are used in many markets like food, grocery, manufacturing, automotive and medical industries.

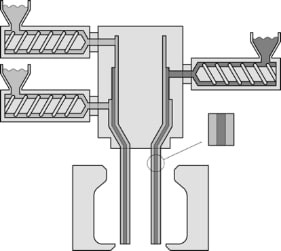

Multi-layer package is produced with co-extrusion direct blow molding machine which has extruders as many as numbers of constructed resins. These resins are layered by flowing along designed resin route and come out from the head as layered parison. Because of this process, direct blow molding is the most suitable machine to produce multi-layer package.

Now we understand what multi-layer bottle is, so let’s see what “functional resin” we can use.

Barrier layer

Barrier layer is the most popular layer when it comes to multi-layer package.

Usually EVOH (ethylene vinyl alcohol copolymer) or PA (polyamide) resin is used for that. These resins are characterized by barrier function like protecting contents from oxidation or volatilization. EVOH is impermeable to oxygen and PA is hard to react to chemical.

Below are common functional packages using barrier layer and sample layer composition.

Seasoning/food

Mayonnaise

| Layer | Inner | Outer | ||||

| 6 | LDPE | Regrind | Adhesive | EVOH | Adhesive | LDPE |

Dressing

| Layer | Inner | Outer | ||||

| 6 | PP | Regrind | Adhesive | EVOH | Adhesive | PP |

Cosmetics

Mascara

| Layer | Inner | Outer | |||

| 5 | PP | Adhesive | EVOH | Adhesive | PP |

Agrichemical

Pesticides

| Layer | Inner | Outer | ||

| 5 | PA | Adhesive | Regrind HDPE(View) | HPDE HDPE(View) |

Automobile/Motorcycle

Fuel tank

There are more other advantages of multi-layer package. We’ll introduce that next time.

| Layer | Inner | Outer | ||||

| 6 | Hight molecular weight PE | Adhesive | EVOH | Adhesive | Regrind | Hight molecular weight PE |

Hot topic!

We’ve started direct blow molding school since last year. We have classes for beginner people, intermediate skilled people and maintenance lectured in the both classroom and practical training with our test machine. We’ve got a favorable reception from many customers in these classes and our text. There are only Japanese classes for now, but we’re planning to open the classes in English in the future. We’ll keep you posted.

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store