Spotlight on Multi-Layer Tubes

4/15/25

This issue focuses on multi-layer tubes and the advantages of Tahara’s extrusion blow molding machines in their production.

Multi-layer tubes are commonly used for packaging condiments, like wasabi, ginger, etc. These tubes consist of 5 to 6 layers, including EVOH (Ethylene Vinyl Alcohol).

The EVOH layer provides oxygen barrier properties, which help extend the product’s shelf life and contribute to reducing food waste.

When the EVOH content is 3-5%* or less, the tube can be classified as a mono-material, making it more recyclable. This feature has led to the recent use of EVOH-containing multi-layer tubes as an alternative to aluminum tubes for toothpaste packaging.

There are 3 ways to mold multi-layer tubes.

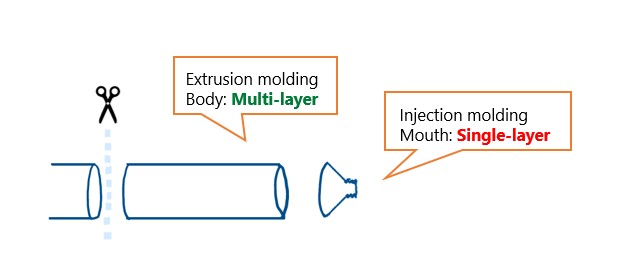

A: Extrusion molding + Injection molding

A multi-layer cylindrical body part is formed by extrusion molding. It is combined with the mouth part formed by injection molding.

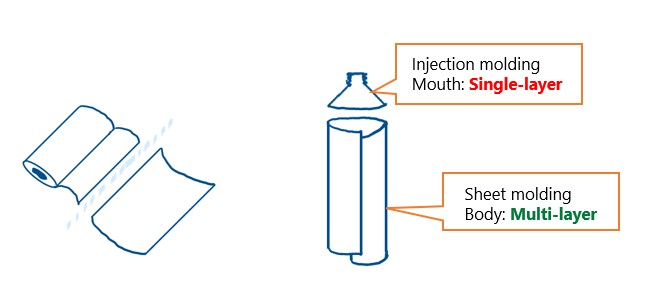

B: Sheet formed + Injection molding

Roll and bond the multi-layer sheet formed by sheet molding. It is combined with the mouth part formed by injection molding.

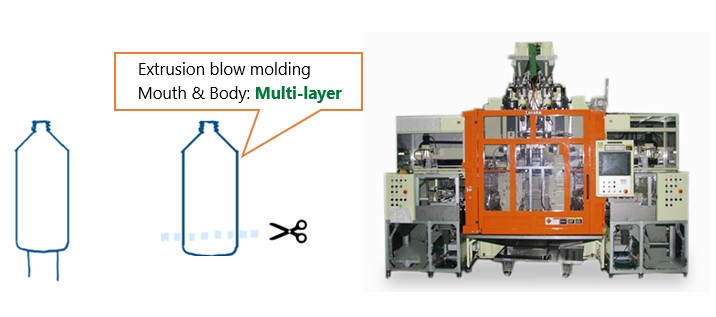

C: Extrusion blow molding machine

The mouth and body parts are formed by extrusion blow molding, and the bottom part is cut off inside the extrusion blow molding machine.

The advantages of C over A & B are stated below.

- The processes A & B require combining the mouth

and body parts that are molded separately. C molds

the mouth and body together and cuts the bottom in the extrusion blow molding machine,

completing everything in one step. - In the case of A & B, the injection-molded mouth part cannot be multi-layered, so this

part lacks the barrier function of EVOH. In the case of C, the mouth part is also multilayered

with EVOH providing barrier functionality to the entire product.

We will now explain the reasons for recommending Tahara machines when molding multilayer tubes using extrusion blow molding machines.

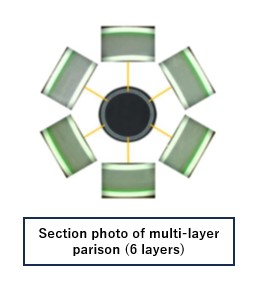

1.High-quality bottle:

We can optimize and mold expensive resins like EVOH and

Adhesive into thin, uniform layers. Even when thin, the EVOH layer

never breaks. We can produce high-quality bottles while

minimizing the use of expensive resins. This is because Tahara has

a long history of manufacturing extrusion blow molding machines

for 6-layer food bottles. We design, process, assemble, and test

everything ourselves at our factory in Japan. This in-house

approach gives us full responsibility and enables us to provide

high-quality multi-layer heads.

2. One-stop service:

As mentioned above, since we manufacture both extrusion blow molding machines and multi-layer heads in-house, we can provide a one-stop service.

3. Customization flexibility:

While we have extensive experience with numerous projects, we welcome built-to-order requests. We manufacture according to your specific requirements, customizing the resin layer ratio and layer composition as needed.

Here is a common sample layer composition that we have manufactured.

| Inner | Outer | |||||

| Rasin | PE(PP) | REG | AD | EVOH | AD | PE(PP) |

| Ratio | 15% | 60% | 2.5% | 5% | 2.5% | 15% |

For any further inquiries or questions, please contact your sales representative or use the form on our website!

*Note: The specific percentage for mono-material classification may vary according to each country’s regulations.

China plas 2025

We are proud to announce that Tahara, Japan’s No.1 extrusion blow molding machine manufacturer, will be exhibiting at CHINAPLAS 2025 from April 15-18, 2025!

Dates: April 15-18, 2025

Location: Shenzhen World Exhibition & Convention Center (Bao’an), PR China

Booth: JSW Booth, 11J41

Visit us to discover our cutting-edge extrusion blow molding technology.

For further information, please feel free to contact us.

TAHARA MACHINERY LTD.

2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan

Parts Store

Parts Store