Improve production efficiency with Auxiliary equipment

9/7/23

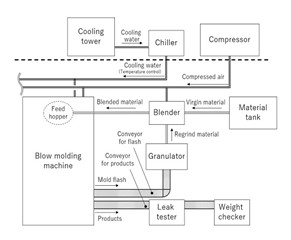

At this time, we would like to introduce useful auxiliary equipment that improves production efficiency. The Auxiliary equipment enables you to save labor working around an extrusion blow molding machine. We provide a one-window service of whole machines & equipment like suggesting them with applicable specifications, making a whole layout, and installing them at your factory by connecting each machine. That would be the best solution for improving production efficiency and a recent labor shortage.

Mold

We offer a mold with our extrusion machine as a set if requested. Based on the client’s product drawing, we consult our reliable Japanese mold manufacturer and they make a high-quality mold. We adjust the mold, set the molding conditions, and try the test molding with the client’s new extrusion blow molding machine in our factory before we ship. It contains a one-time slight modification. This set offer is more suitable for the factory that is newly trying to start an extrusion blow molding business.

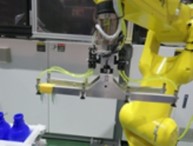

Product take-out robot

Multi-axis robots can be installed in a small space and used in various ways. You can use a robot instead of a product conveyor to take molded bottles out of an extrusion blow molding machine and transfer them to other equipment like a leak tester and a weight checker.

Flash conveyor

Flashes in the extrusion blow molding machine refer to the excess plastic material that remains on the body of the bottle. They are usually removed inside the molding machine during operation and fall on the floor. Flash conveyors are set under the molding machine and transfer these flashes to the grinder. We have 2 types of flash conveyors. One is a flat conveyor which is set under the molding unit and the other one is an S-shape conveyor to transfer flashes from the flat conveyor to the grinding machine.

You might want to install the above helpful equipment in your factory. We’re willing to advise the most suitable plan for your factory. Please don’t hesitate to ask us.

Hot topic!

We’re going to exhibit one of our new lineups of extrusion blow molding machines at IPF Japan 2023, held from November 28th to December 2nd in Tokyo. IPF Japan is one of the biggest plastic tradeshows in the world. We innovate the construction of all units and adopt a new clamping mechanism. That makes the layout more space-saving and achieves larger numbers of heads for multi-cavity than ever. There are more attractive specifications and we’ll update you on our new machines regularly. Please find the details of IPF Japan from the following link.

https://www.ipfjapan.jp/english/

We’re pleased to inform you of one more piece of good news: We will collaborate with Delta Engineering at IPF Japan. They are a global provider of downstream solutions for the blow molding industry. They manufacture various labor-saving machines and equipment for quality control, packaging, unscrambling, conveying, take-out, finishing, coating, and buffering of plastic bottles and containers. For example: leak testers, weight checkers, bottle conveyors, baggers, case packers, cutting machines, plasma coaters, and many more.

Delta Engineering and TAHARA can suggest solutions to improve your efficiency, according to your specific needs and factory layout.

Please come and see our booth at IPF Japan.

For further information of our blow molding machine, please feel free to contact us.

TAHARA MACHINERY LTD.

2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan

Parts Store

Parts Store