TAHARA Newsletter Vol. 1

6/1/17

In This Issue

1.A brief history of TAHARA

2.About our machine

3.IPF2017

1.A brief history of TAHARA

We, TAHARA, have introduced our very first all electrified blow molding machine(BMM) in 1994, and kept developing our technology to meet our customers’ variety needs. We have been so far supplying more than 1,000 machines over 20 years. Today, we have gained 80% of domestic market share. Now, we are aiming to expand our business toward the international market.

2.About our machine

As we mentioned earlier, our BMM is now fully electrically driven. To compare with a former generation machine, hydraulic BMM, new machines can provide 3 benefits.

Clean Environment

Electric BMM will not give you any risk of oil leakage. This is simply because we do not use hydraulic system anymore. It makes machine maintenance easier. This feature is suitable to customers who need to have clean rooms for their production. Besides, electric BMM significantly reduced its noise.

Higher Performance

By using AC servo motors, molding cycle time is faster and more stable. Machine operators are now able to set and adjust the machine operating condition by the control screen without stopping production line. The electric BMM can save and reload each product’s molding condition data in the control panel.

Energy-Saving

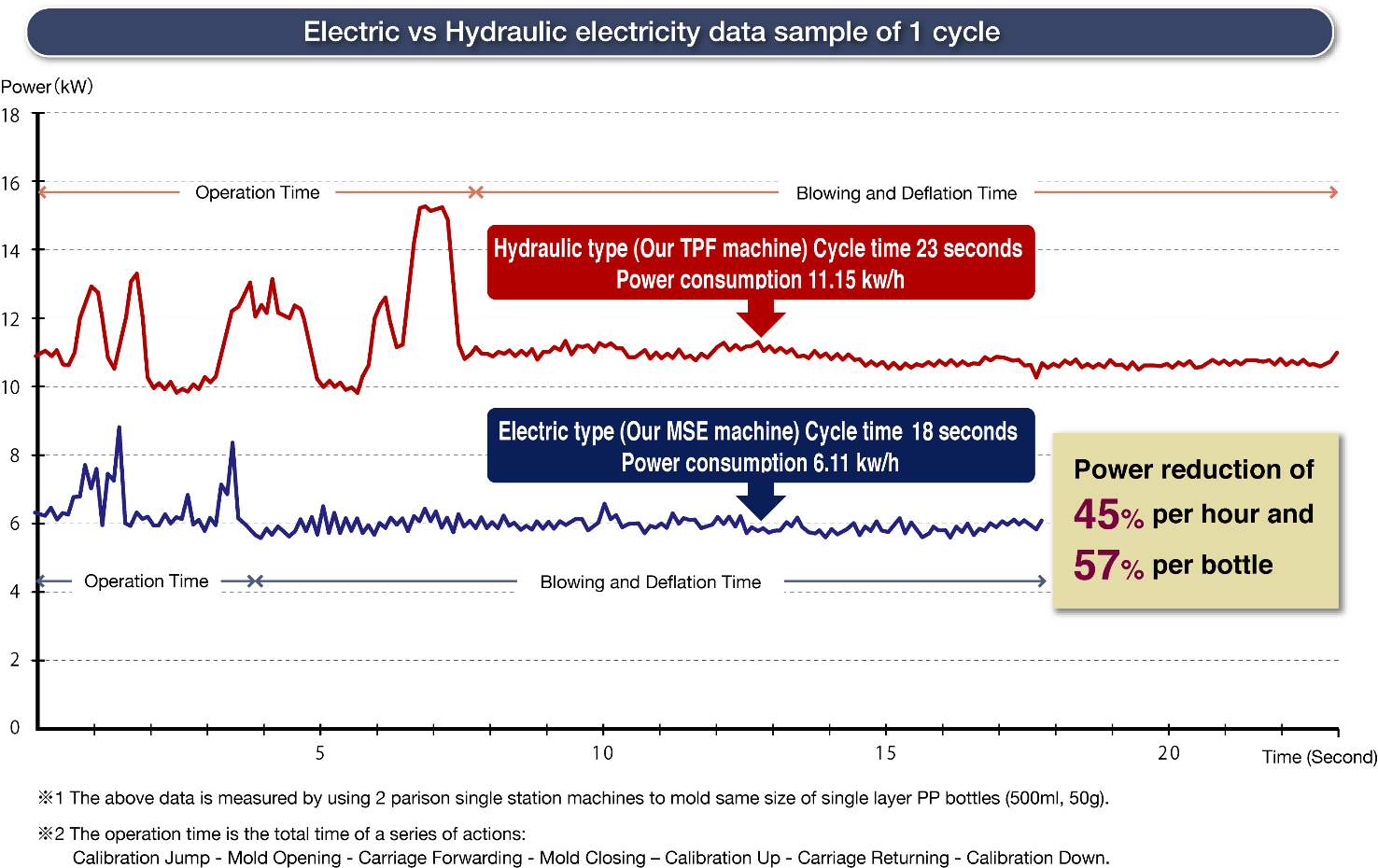

Comparing to our hydraulic BMM, we successfully have reduced approximately40~60% of the power consumption. (Refer to the chart below)

Moreover, we have developed our own unique technology.

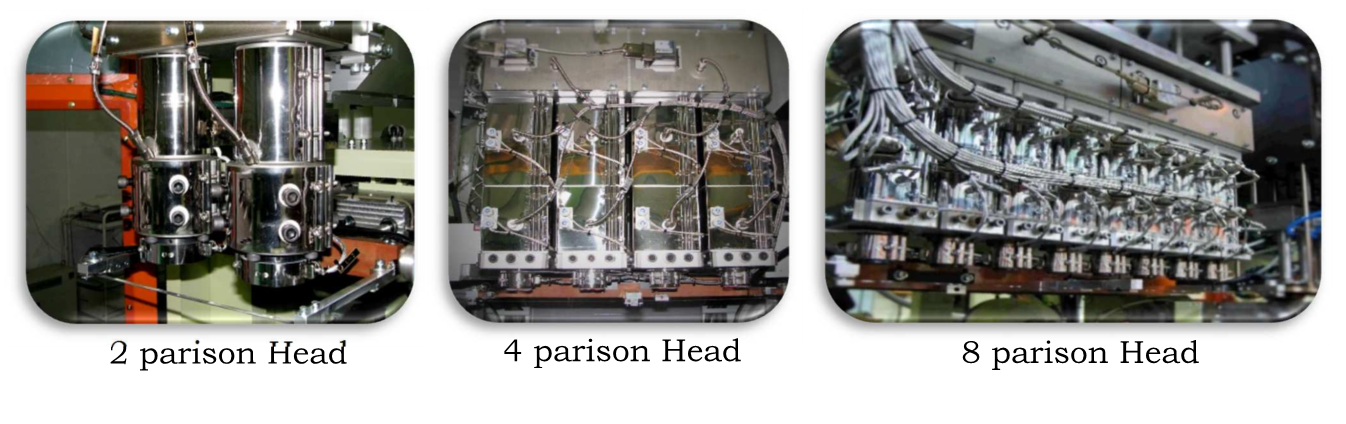

Head

It is one of the most important parts of the BMM which we design and

manufacture at our main factory. We carefully design Head to meet our customer needs. 3D simulation is often used for the flow analysis of Head design. If you have any special specification, please contact us. We are happy to discuss for your request.

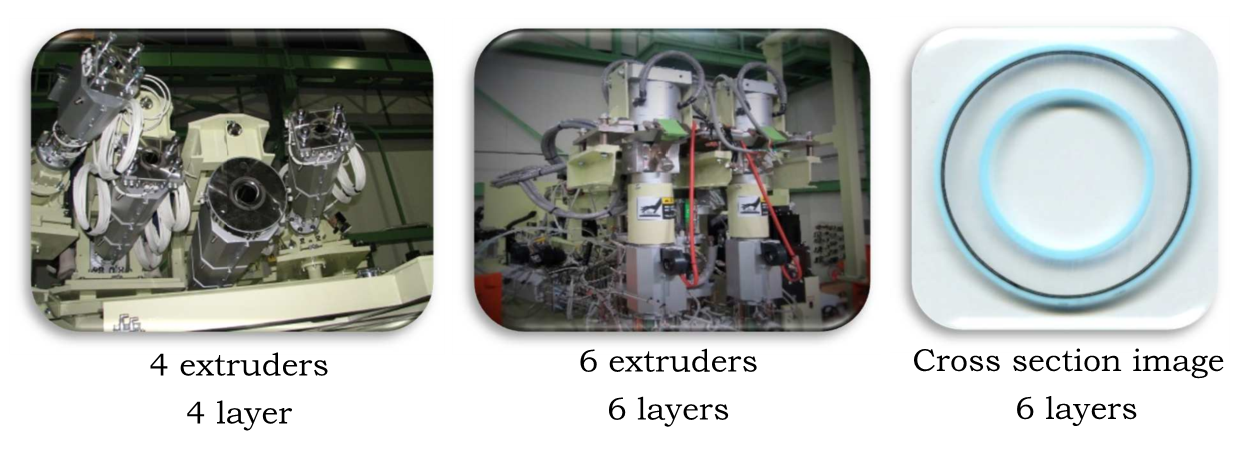

Multi-Layer

Our electric BMM can produce multi layers products. Multi layers products are made by resin which is antioxidant one, recycled one and so on. Experts in our office precisely calculate each layer thickness to satisfy your demands.

3.IPF2017

IPF, International Plastic Fair, is one of the biggest plastic-related exhibition which is hold every 3 years in Japan. In IPF 2014, we introduced new design BMM, HES type and HPS type. Please visit our website for further details.

Now, we are happy to announce that we are going to participate IPF 2017. This year IPF will be held October 24th to 28th. We are developing and manufacturing new machine which equipped some groundbreaking technologies. We are looking forward to seeing you at our booth.

For further information, please contact us

TAHARA MACHINERY LTD.

https://www.tahara-mc.com/en/

Parts Store

Parts Store