What makes difference between TAHARA and other makers?

10/1/21

How would you choose maker when you install new extrusion blow molding machine?

We can offer many strengths over other makers, which helps you to decide.

1st maker which launched Fully electric blow molding machine

Nowadays, it becomes more common to choose fully electric blow molding machine instead of hydraulic machine from the aspect of energy saving. In addition to that, fully electric blow molding machine promises clean environment and is more cost effective than hydraulic blow molding machine.

We manufactured the world’s first fully electric blow molding machine in 1994 and we’ve sold over 1,100 of them until now, which made us a pioneer of fully electric blow molding machine. Therefore, we are the most experienced maker in the world and we can offer the most appropriate and reasonable machine to you.

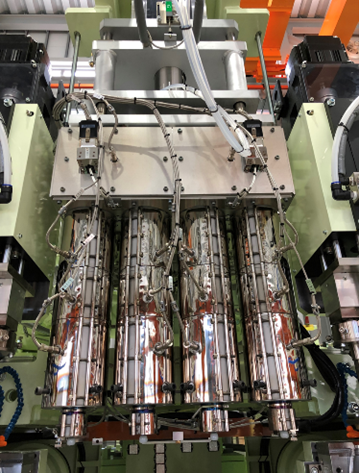

Design of screw & co-ex head

Screw and head design are the most important parts of the blow molding machine. Screw needs to be designed to mix molten resin sufficiently and head design requires precise calculation based on accumulated data to avoid resin retention which causes resin burnt. Efficient design shortens the time of changing color.

Unlike other makers, we don’t outsource these designs. We calculate, design, process and assemble these unit by ourselves based on plenty of experience and knowledge even co-ex heads for multi-layer package, therefore wall thickness at any point of each layer is uniform even multi-layer package. From above reasons, we can design co-ex head according to your request in any resin grade, with any layer composition and in any layer ratio.

We can offer exact machine which meets all your needs.

| Section photo of multi-layer parison (6 layers) |

Reliable quality

Durability of our blow molding machine is second to none. We’ve analyzed in various methods when designing machines like structure analysis for reducing machine weight. As long as you conduct periodic maintenance and overhaul, you can use our machine for more than 20 years. Taking a long-term view, our machine is the best to introduce. Less maintenance and less trouble enable you to increase productivity.

Hot topic!

We’re opening a private showroom at 1st Nov, 2021 in our warehouse. We’ve displayed bottles and packages that can be produced by our blow molding machine. Displaying various industry’s packages by the machine types, we can have a meeting with showing them.

Please feel free to come and see it when you visit Japan.

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store