What bottle can we make with our Blow molding machine? Single-layer package

8/1/22

Single-layer package

Single-layer package is widely used in various places. You can produce good-quality package stably in even wall thickness with our fully electric extrusion blow molding machine.

Let’s see what you can produce with our machine!

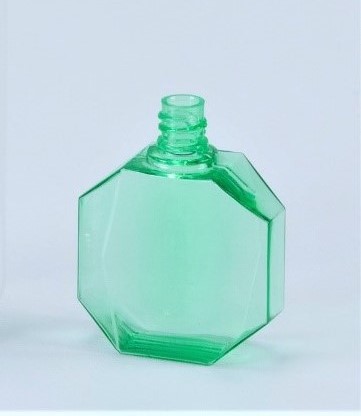

Small lot PET bottle

PET resin is sometimes adapted because of attractive appearance and transparency especially in cosmetic and medical market. Colorful and clear bottles can be produced by adding master batch.

If it is small-lot production, extrusion blow molding may be better than stretch blow molding in terms of cost. Initial cost of extrusion blow molding is usually more reasonable than stretch blow molding machine. One of the reasons is that stretch blow molding requires at least 2 pcs of mold, mold for injection blow and extrusion blow, which makes much more expensive than blow mold. We recommend multi-parison head like 2 heads, 4heads. It can much help your production of “many models” in “small quantities”.

We’ll also offer resin dryer which is necessary for molding with PET resin. Please feel free to ask us, then we’ll advise best way to produce.

Industrial packaging

BIB (bag in box), large chemical bottle and stackable jerry can are classified as industrial packaging. According to the use and your demand, we offer both multi-layer and single-layer machines. Leakage and breakage cause serious danger, so we emphasize that stable molding is one of our advantages. You can produce products that has even wall thickness and elaborate mouth shape, and is durable with our machine.

Extrusion blow molding machine can produce product with handle without any post-processing. After taking out of machine, what you need to do is just boxing.

Hot topic!

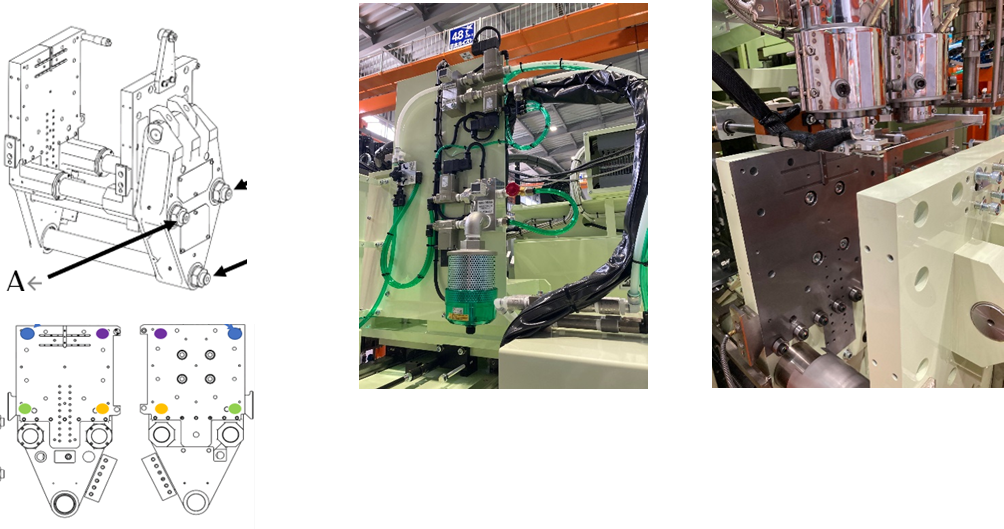

We’ve started offering periodic inspection plan in Japan. Our mechanic examines our electric extrusion blow molding machine in our customer’s factory. Items we check are that parallelism of the clamping unit, clamping force, wear of each part, gearbox, cutter and so on with our inspection jig according to our check sheet. We report recommended replacement parts and timing of overhaul after the inspection. Our fully electric blow molding machine has durability and can be operated for more than 20years by conducting periodic inspection and maintenance.

This service is limited in Japan for now, but we’re planning to expand to overseas customer in the near future. Please allow us to inform you when we start it.

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store