What bottle can we make with our Blow molding machine? Multi-layer package Part 2

4/1/22

Multi-layer package Part 2

What would you do if you add more value to your plastic products for differentiation?

We’ll offer some suggestions divided into several times!

Continuing from the previous issue, we’ll introduce multi-layer package. Multi-layer package consists of more than 2 layers to add useful functions. The laminated wall consists of PE/PP and other functional resin layers. In this time, we’ll suggest the ways to use functional layer in a laminated wall and add more value on your bottle other than barrier layer we introduced in the previous issue.

Gloss layer

To attract consumer, gloss layer is adapted especially in cosmetics bottle. Using PET-G or EVOH resin on outer layer, bottle gets shines and looks be glossier. Adding pigment into the inner layer, color becomes deeper, which appeals luxuriousness and enhances value.

Shampoo

| Layer | Inner | Outer | ||

| 4 | HDPE | Regrind | Adhesive | PET-G |

Sunscreen

| Layer | Inner | Outer | ||

| 4 | HDPE | Regrind | Adhesive | EVOH |

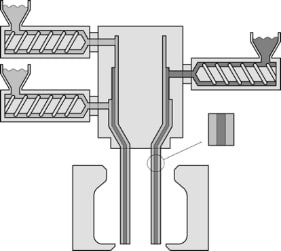

View stripe

You can check remaining contents, if the bottle has view stripe on its side. This bottle can be produced with Co-ex direct blow molding machine by inserted stripe uncolored resin into the colored parison wall inside head. With our highly skilled head design, you can mold straight and cleared view stripe.

Agrichemical

| Layer | Inner | Outer | ||

| 5 | PA | Adhesive | Regrind HDPE(View) | HDPE HDPE(View) |

Recycled resin

Reducing the use of plastic material is one of the ways to contribute to SDGs.

Many molding makers use regrind resin (crushed flashes and defected product) by mixing them into virgin resin. With 3layer Co-ex direct molding machine, you can put regrind resin in middle like “sandwich”. It means virgin layers are used in outer and inner layer, and regrind layer is used in middle layer. Using virgin layer in outer and inner layer, appearance and inner surface are still clean even using regrind resin to bottle. This way is also applied when you use resins which cannot be used alone like being difficult to mold alone, having a light scent, being easy to occur burnt and black point or being not hygienical.

More specifically, the rest flashes of other products or bio degradable resins would also be applied to this “sandwich”.

In addition, if you use master batch in only outer layer, you can reduce the cost and use of master batch. If contains are easy to react to chemical included in master batch, you can avoid it by using natural resin in inner layer.

Automobile oil

| Layer | Inner | Outer | |

| 3 | HDPE | Regrind | HDPE |

Mayonnaise

| Layer | Inner | Outer | ||||

| 6 | LDPE | Regrind | Adhesive | EVOH | Adhesive | LDPE |

We’re willing to try different layer composition with you. We’ll design resin route of Co-ex head based on your requested layer composition and ratio applying our accumulated knowledge. Please let us know if you have any other ideas!

Hot topic!

We plan to display our new developing machine at an exhibition K-2022 in Düsseldorf. Same as previous time 2019, we’re going to collaborate with Japan Steel Works Japan and share the booth at Hall 13. Displaying our cutting-edge direct blow molding machine, we’ll introduce our advantages in functionality and durability of our machine. Details are to be announced!!

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store