TAHARA Fully electric molding machine lets you implement sustainable business! Part 2

8/1/21

Part 2

The sustainable economy is now key issue to tackle for many companies and it will be your competitive advantage at the same time. We suggest some solutions our machine can do and hope this newspaper helps you to update on the latest blow molding trend and refine your business strategies.

Reducing Electric Consumption

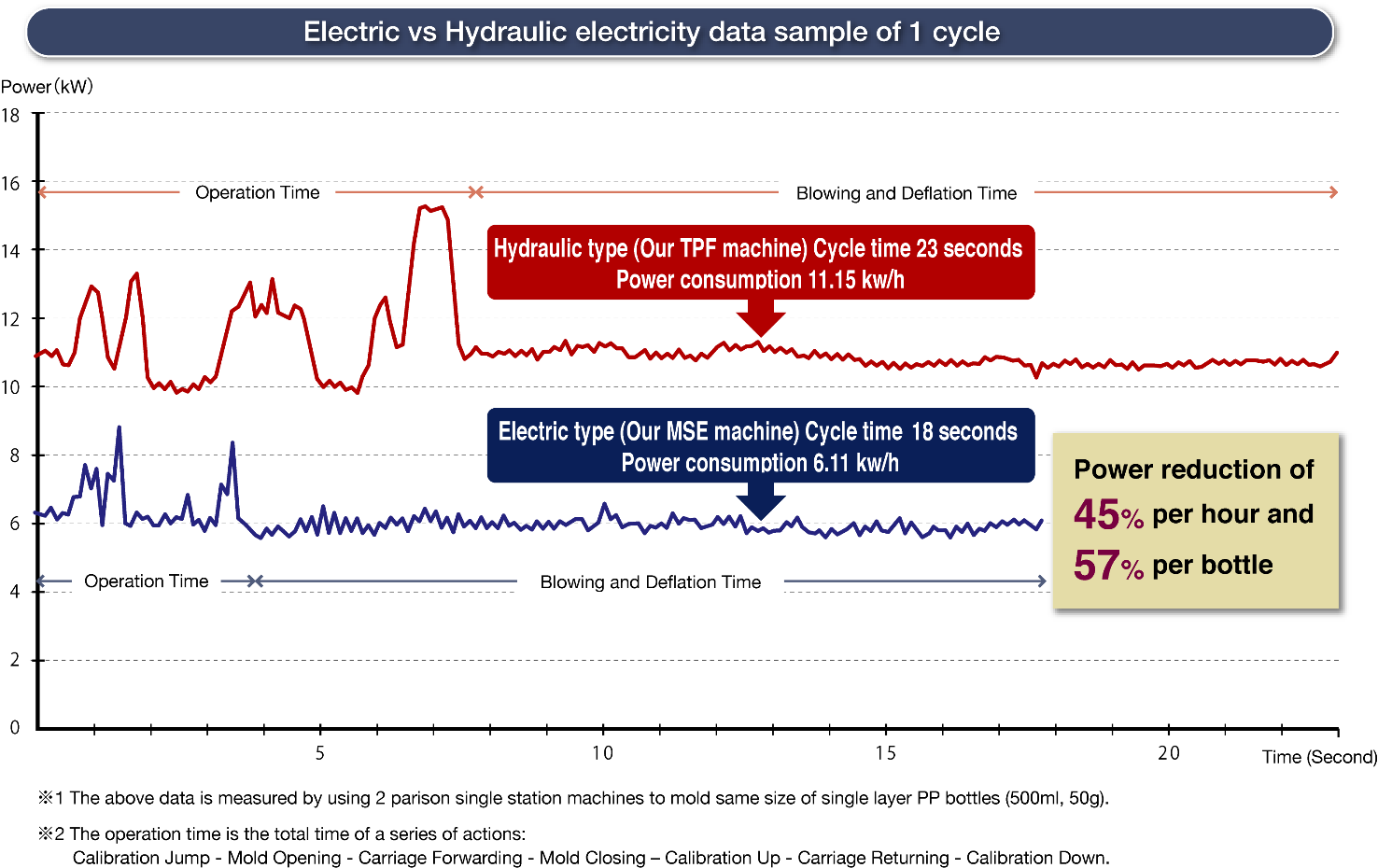

Fully electric blow molding machine is superior in saving a consumption of electricity to oil hydraulic blow molding machine. Fully electric blow molding machine reduces approx. 40-60% of the electric power consumption compared to oil hydraulic machine which we had manufactured before. One of the reasons is that oil hydraulic machine requires constant electricity during sliding or moving each unit to run oil hydraulic pump. On the other hand, fully electric blow molding machine requires electricity only when each unit starts and stops moving. That is clear from below chart.

In addition to the above factor, electrical control enables high repeatability and accuracy of each unit’s movement, which reduce defective rate and dry cycle time. That shortens operating time and cost. Consequently, you can save more electricity.

We launched fully electric blow molding machine in 1994 for the first time in the world. Since then, we have manufactured more than 1,100 of Fully electric blow molding machines. Therefore, we have much more knowledge and experience in fully electric blow molding machine than other makers. Furthermore, we select Mitsubishi electric for all electric components, which helps each of them works well together. Thus, we can offer the best machine.

Plant-based Materials

Due to recent global plastic problems, consumers tend to choose eco products and many resin makers produce plant-based resins and biodegradable resins. We have testing machines in our factory and we’re actively involved in test manufacture. We’ve conducted experimental molding using biodegradable resin (PLA[1]) cooperating with resin maker.

If you’re planning to try test-molding using plant-based or biodegradable resin, please feel free to ask us. We are willing to help you to create new product. Please refer to below link for further information. We have single-layer machine, co-ex machine and injection blow molding machine for testing.

https://www.tahara-mc.com/en/techinfo3

[1] PLA (Polylactic Acid)

Hot topic!

Since we joined The Japan steel works, Ltd. (JSW) Group in 2006, JSW and TAHARA have maximized synergy effect by sharing technique. TAHARA has generally manufactured small size machine and JSW has manufactured especially middle and large size machine.

From October 1st 2021, JSW is going to transfer of business of manufacturing middle and large size machine to TAHARA (except the machine for fuel tank). After transfer, we’re going to deal in not only small machine for small packages and bottles but also middle and big machine for bigger products like plastic drum, IBC (Intermediate Bulk Container) and Filler pipe. We will be integrating technical capabilities and enhancing our competitiveness more than ever.

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store