Eco-Friendly Bottles produced by our blow molding machines

12/27/24

| TAHARA Newsletter December. 2024 |

We must adapt to a society that is transitioning to sustainability. In this edition of our newsletter, we’re pleased to introduce eco-friendly bottles made using our advanced extrusion blow molding machines.

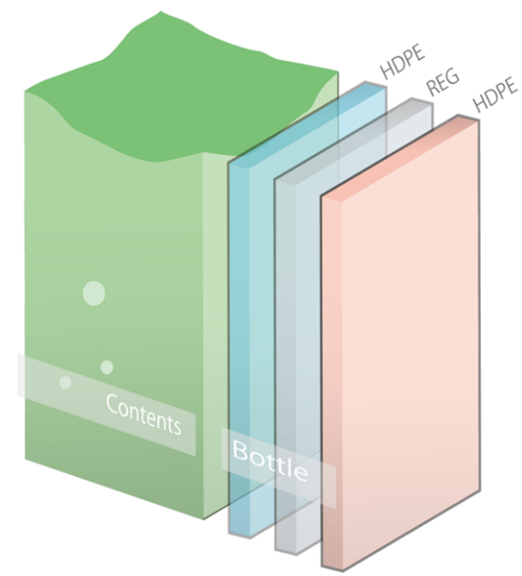

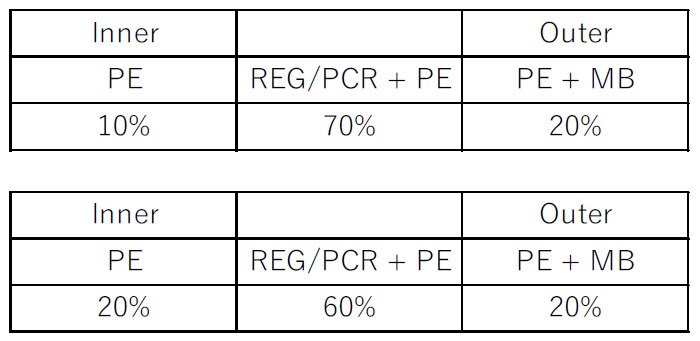

3-layer Bottle

3-layer Bottle

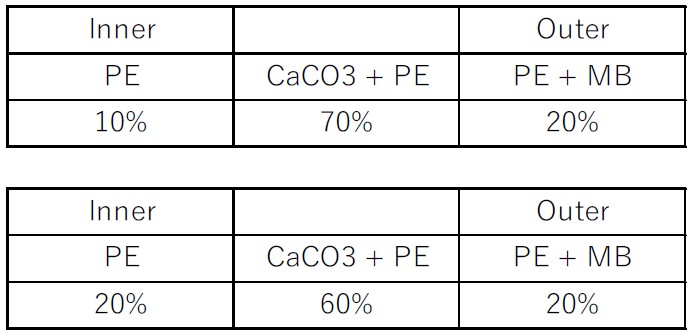

This type of bottle has become quite common in recent years, especially in Europe. It uses PCR (post-consumer Recycled) material and regrind (crushed material) in the middle layer, while the outer and inner layers are made from virgin resin. While PCR and regrind materials may not always have consistent quality, using them in the middle layer and sandwiching with the virgin layer, allows us to maintain a clean and attractive appearance on the surface of the bottle. The use of virgin resin for the inner layer helps prevent any potential chemical reactions between the contents of the bottle and any impurities in the recycled materials, ensuring the safety and integrity of the product. Since the masterbatch can only be used for the outer layer, the use can be reduced.

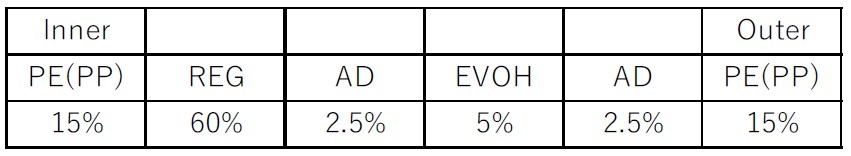

【Sample layer composition】

Alternative to glass containers

Alternative to glass containers

Switching from heavy glass containers to lightweight plastic options can offer a more convenient and cost-effective solution. The rising costs and closures of many glass container manufacturers, particularly those producing special-spec glass containers, have made obtaining glass containers increasingly challenging.

There are 3 Eco-Friendly benefits of switching from glass containers to plastic containers.

The first benefit is the reduced environmental impact. Since plastic containers are lighter than glass, they help reduce CO2 emissions during transportation.

The second benefit is energy efficiency. The manufacturing process for glass containers requires high-temperature furnaces, which consume significantly more energy compared to the production of plastic containers.

Finally, plastic containers are more durable and less prone to breakage, which helps reduce waste.

Glass containers have the ability to prevent oxygen permeability, which is why many manufacturers continue to adopt glass for its properties. With a multi-layer plastic bottle that includes EVOH, you can maintain oxygen barrier properties similar to glass. While it is less effective than a glass bottle, it provides significantly better oxidation protection compared to single-layer PE, PP, or PET bottles. We have multiple customers in TAHARA that have converted to multi-layer plastic bottles. It allows the material to be recycled as a mono-material when used with polyethylene, and generally, if the EVOH content is below 5%.

To preserve the clarity feature like a glass bottle, we suggest a different style of multi-layer plastic bottles. Using a multi-layer container made from PET-G and EVOH maintains the desired level of transparency. Our technology ensures that the layer ratio remains consistent at every point along the circumference, which allows us to minimize the use of expensive resins like EVOH.

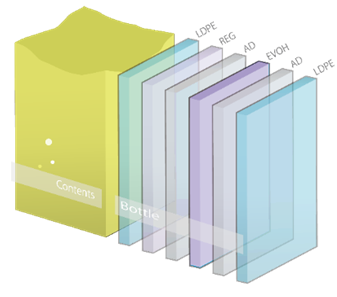

【Sample layer composition】

Calcium carbonate

Calcium carbonate

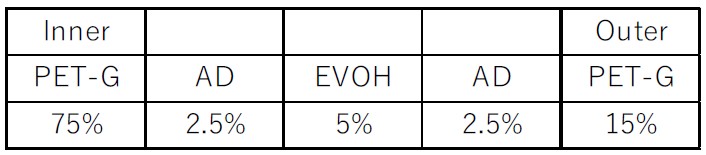

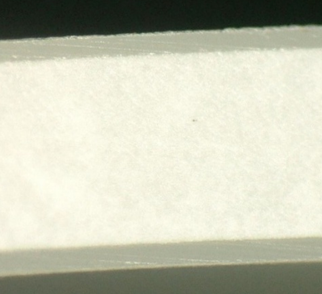

We can effectively reduce the amount of resin used by mixing calcium carbonate with resin. Adding calcium carbonate improves the cooling process, resulting in shorter cycle times. Additionally, it makes the removal of the flash easier compared to using plastic alone. Adding calcium carbonate can make the product more susceptible to scratches, and the material may react chemically with some contents. Therefore, we recommend co-extrusion molding using a 3-layer structure.

【Sample layer composition】

Let’s produce eco-friendly bottles using our fully electric eco-friendly extrusion blow molding machines.

Hot topic – Introducing Our New YouTube Channel!

We are excited to announce the launch of our official YouTube channel. On this channel, we will be sharing a variety of content, starting with an introduction to our company, followed by in-depth videos on our extrusion blow molding machines and the cutting-edge technologies behind them.

Our first video, the company introduction, gives you a tour of our factory, office, showroom, and testing facilities. It’s a great opportunity to learn more about who we are and what we do.

We invite you to check out the video and stay tuned for more exciting content. Don’t forget to hit the Like button and Subscribe to our channel for the latest updates on our products and innovations!

www.youtube.com/@TaharaMachineryJapan

| For further information, please feel free to contact us. TAHARA MACHINERY LTD. 2-1 Kaguro-Minami Inzai Chiba 270-1369 Japan https://www.tahara-mc.com/en/contact https://www.linkedin.com/company/tahara-machinery-ltd |

Parts Store

Parts Store